What are Electric Diaphragm Pumps?

What’s the biggest difference between electric and air operated diaphragm pumps ? Their power source. Electric diaphragm pumps use electricity, while air operated diaphragm pumps (AOD pumps) get power from compressed air. Switching to an electric diaphragm pump, users can save up to 80% on operating costs and energy savings. Electric diaphragm pumps, also known as sealless process pumps for specific designs, are used to transfer fluids efficiently and reliably.

Depending on the technology, electric diaphragm pumps can transfer liquids with low, medium or high viscosities, as well as liquids with suspended solids. They can handle many aggressive chemicals such as acids because of the wide variety of body construction materials (polypropylene, stainless steel, aluminum, etc.) and diaphragms (santoprene, PTFE, etc.)

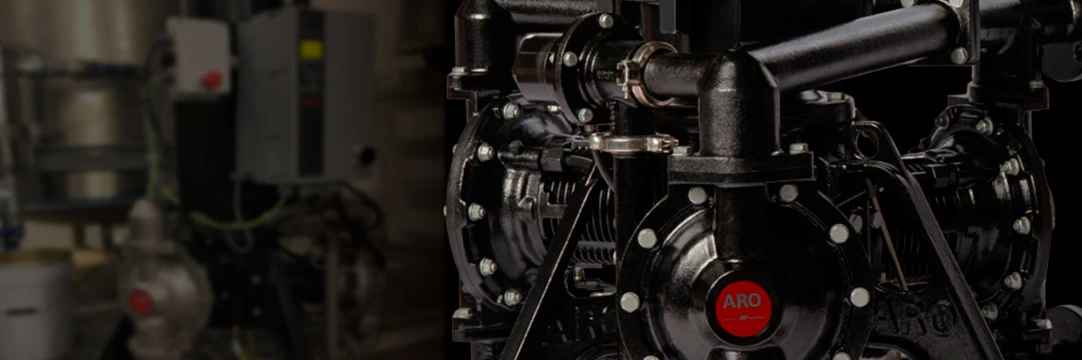

Electric diaphragm pump can have either two- or three-diaphragm chamber options. ARO offers both technologies, with the EVO Series™ 200 (electric double diaphragm pumps) and the EVO Series™ 300 (electric triple diaphragm process pumps). ARO’s EVO Series™ 300 is the industry leading electric process diaphragm pump and 2023 Pump Industry Awards’ Product of the Year.

"100% electric drive for energy efficiency: with zero compressed air needed. This eliminates costly compressed air, increasing cost savings and tremendously decreasing energy consumption."

How Do Electric Diaphragm Pumps Work?

These pumps operate using a linear back-and-forth motion through a crankshaft system. This creates suction and discharge of the fluid. Let's explore their working mechanism:

- Suction Stroke: The diaphragm moves away from the pump chamber, creating a low-pressure area. This draws fluid into the pump through an inlet valve, filling the chamber.

- Discharge Stroke: As the diaphragm returns to its original position it compresses the fluid in the chamber, increasing pressure. Then pushing the fluid out through a discharge valve and into the outlet or discharge pipe.

- Valves: They use a ball check valves to control flow direction. The inlet valve allows fluid to enter the pump during the suction stroke. The discharge valve ensures one-way flow during the discharge stroke.

Electric Motor and VFD: An electric motor powers the crankshaft of the pump. Power supply depends on designs and technologies. EVO Series ™ 300 electric diaphragm process pumps of ARO provide the following voltage and frequency options: 3-phase dual frequency 50/60Hz with 200–240V, 380–500V or 525–600V.

The ARO EVO Series 200 electric diaphragm pumps are available with three different gearbox/motor combinations depending on application requirements. They do not include a VFD, but are compatible with local control systems.

What are Electric Diaphragm Pumps Used for?

Electric diaphragm pumps have a wide range of applications:

- Chemical Transfer : the pump’s seamless design is ideal for handling chemicals safely, and delivering precise fluid transfer.

- Paint and Ink : delivers high-quality finishes of paints, varnishes and coatings because of the pump’s ability to provide consistent flow rates for these viscous liquids. The EVO Series™ 300 line 3-chamber design pumps material without shear or pulsation, compared to traditional 2-chamber designs.

- Cardboard , Pulp and Paper : these pumps deliver the highest reliability and efficiency solution for pumping starch glue . The sealless design removes leakage and product loss. Control features allow the pump to deliver the exact flow and pressure to meet demand. A 3-chamber electric diaphragm pump delivers longer intervals between routine maintenance and low pulsation.

- Lithium-ion Battery Manufacturing : these pumps can handle abrasive materials and powders. This makes them great for carbon black and slurry applications, where durability and reliability are crucial.

- Industrial Wastewater : able to pump activated carbon fluids by maintaining constant operation at multiple speeds. Control features allow the pumps to quickly increase flow to discharge large volumes of wastewater based on your requirements.

- Construction Wastewater : filter press filling is a common application with electric diaphragm pumps, used in various industries like ceramic production or construction material manufacturing. By holding sufficient deadhead pressure they properly dry out and control the desired density of the filtered material. Electric diaphragm pump’s torque limit control allows them to increase flow rate and deliver maximum filter press filling, better than conventional pumps of the same size. Pump control features allow users to control the pump from the PLC interface to avoid manual operation.

What are the Advantages of Electric Diaphragm Pumps?

Electric diaphragm pumps offer several advantages:

- Self-Priming: electric diaphragm pumps are self-priming. They draw fluid from a lower level, lifting it to a higher elevation without the need for additional priming equipment.

- Run Dry Capability: ability to operate without fluid. Protecting pumps from damage in case of fluid shortage or power interruption.

- Compatible with a Wide Range of Fluids: including corrosive and abrasive substances. They can also handle different viscosities and temperatures, making them suitable for diverse applications.

- Simple and Compact Design: with fewer moving parts, electric diaphragm pumps have a straightforward design, enhancing reliability and simplifying installation, maintenance and repairs.

- Easy to Transport: often lightweight and compact, allowing for easy transport and ability to move around.

How to Install and to Program the EVO Series 300 Electric Diaphragm Pump?

Need information on how to install and program the EVO Series 300 electric triple diaphragm pump? Check out our tutorial videos on the ARO YouTube channel :