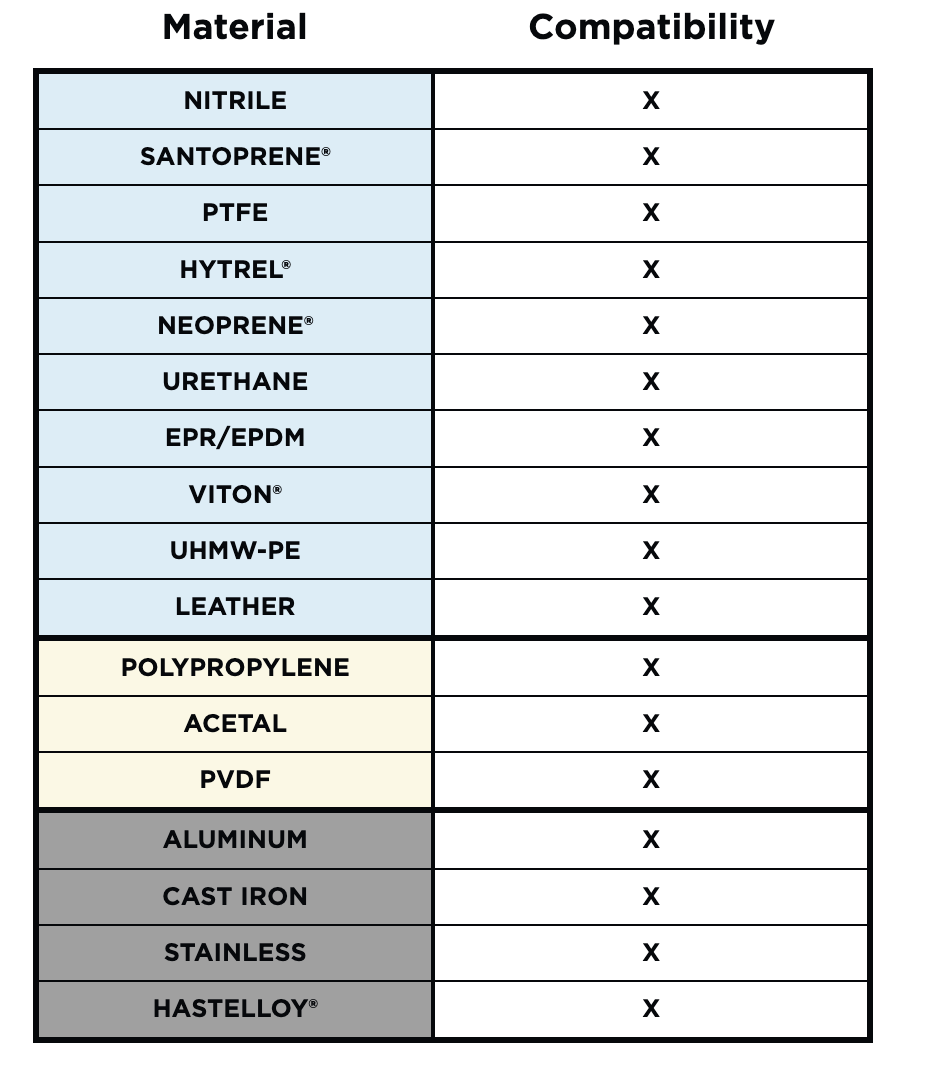

Polypropylene – A general purpose low cost material havingbroad chemical resistance for use in a wide variety of chemical applications.

Kynar (PVDF) – A high performance fluorpolymer resin withexcellent chemical resistance properties. Used for pumping aggressivechemicals at elevated temperature. Material also has excellentmechanical properties.

Groundable Acetal – An excellent material for use in solventtransfer applications. The material incorporates metallic fibers inthe resin to render the material conductive to eliminate static chargebuild up and potential static discharge.

Rating

A = Excellent | B = Good | C = Fair | D = Poor

| Non-Metallic Wet End Materials | Temperatue Limits** | Acid Service | Caustic Service | Solvents (Ketones/Acetates | Hydrocarbons Aromatic/Chlorinated |

|---|

| Polypropylene | +32˚ to 175˚F | A | A | NR | NR |

| PVDF | +10˚ to 200˚F | A | A | * | * |

| Groundable Acetal | -20˚ to 180˚F | D | D | A | A |

*Check chemicalcompatibility guide for part specific solvent or hydrocarbon.

**Maximum temperature is based on mechanical stress only. Certainchemicals can significantly reduce maximum safe operating temperature.