Effective Glue Pumping Systems for Industrial Applications

How to Choose the Right Glue Pumping System for Your Industrial Needs?

Adhesives are important in manufacturing. They are used to bond, seal and secure materials in many processes. Different types of glue are used, so choosing the right glue pumping system is key.

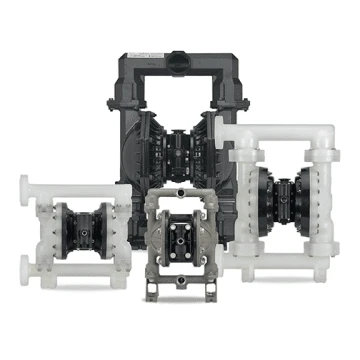

This article explains common glue types, pumping systems and why ARO pumps are a great choice for industrial applications.

What Types of Glue Are Commonly Used in Factories?

Adhesives in industrial settings vary greatly in viscosity and application requirements. Selecting the right glue for your process ensures strong, reliable bonds and efficient production. Common types include:

- Water-based glues: These thinner adhesives dry as water evaporates. They are commonly used in applications like woodwork, paper, and general assembly. Examples include school glue and wood glue.

- Hot melt adhesives: Solid at room temperature, these glues need heat to become liquid. They are widely used in packaging, textiles, and furniture assembly, providing a fast setting time once cooled.

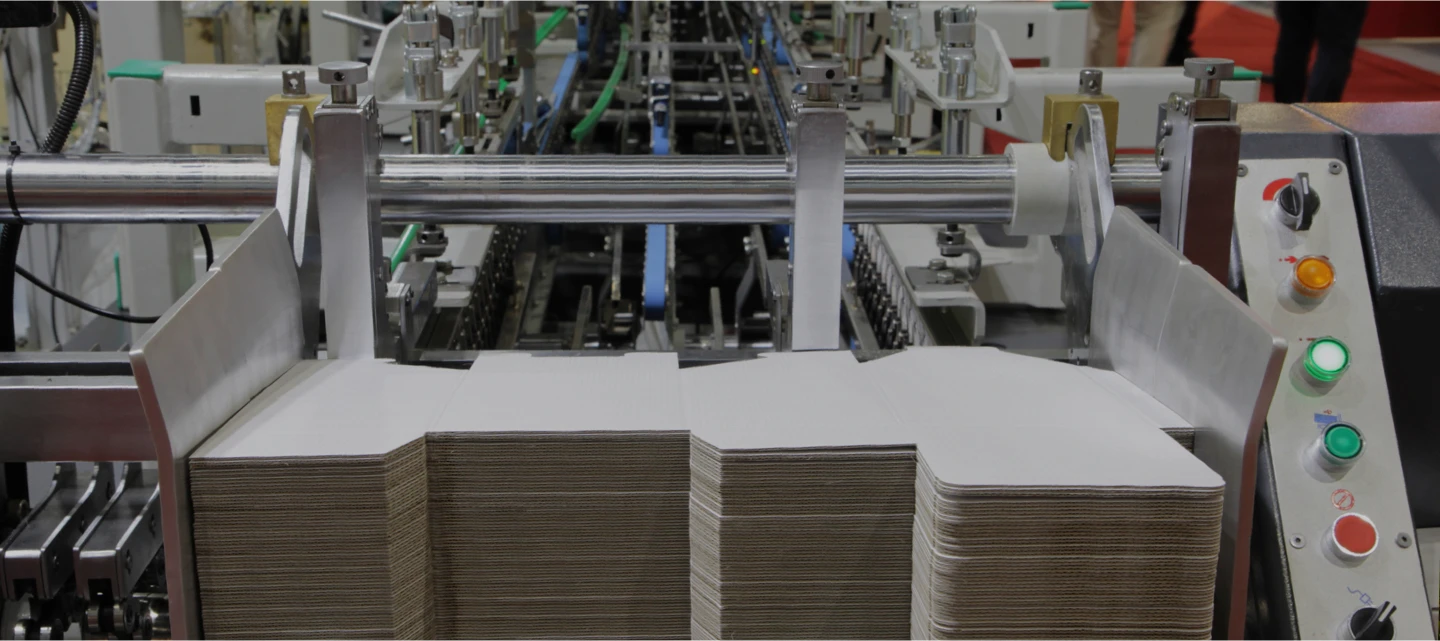

- Starch glue: Essential in cardboard and corrugated board manufacturing, starch glue bonds paper layers for a strong, durable hold.

- Epoxies: Highly durable, two-part adhesives. Ideal for bonding metals, plastics, and composites where strength and durability are key.

- Polyurethane adhesives: Known for their flexibility and rigidity, they are used in both structural and non-structural applications.Examples: construction and automotive industries.

Given the varying properties—such as viscosity, curing time, and thickness—choosing the right glue pumping system is essential. Why? To maintain consistent, reliable adhesive application in industrial settings.