Ensuring Hygiene and Efficiency in Every Transfer with FDA Diaphragm Pumps

The food and beverage industry is governed by strict hygiene and safety standards, making the choice of equipment crucial. A key component in this sector is the food grade diaphragm pump: it plays an essential role in ensuring the safe and efficient transfer of ingredients and products.

As outlined in the Food & Beverage Industry Pumps Market report , the demand for specialized pumping solutions is on the rise. It is mainly driven by the need to meet regulatory requirements and avoid contamination. Non-compliance not only risks the integrity of the products but also invites significant financial penalties.

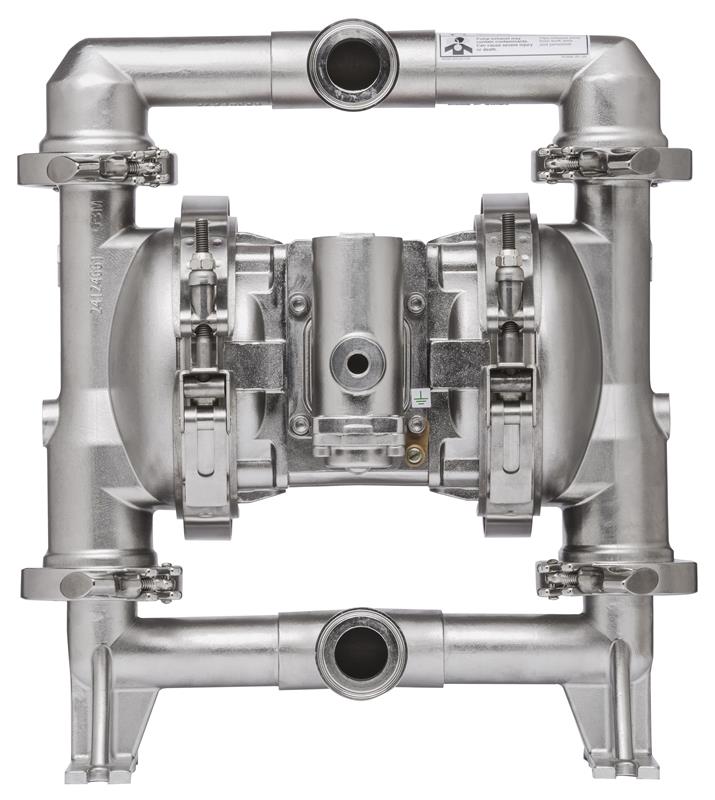

ARO, a leading name in the industry, offers Air-Operated Double Diaphragm (AODD) Pumps that are globally recognized for their compliance with FDA regulations . It makes them ideal for various applications in the food and beverage industry. These pumps not only ensure the safety and efficiency of food processing operations but also meet the most stringent hygiene standards.

FDA-Compliant AODD Pumps for the Food/Beverage Industry

Compliance with U.S. Food and Drug Administration (FDA) regulations is non-negotiable in the food and beverage industry. ARO’s FDA-compliant food grade diaphragm pumps are perfectly suited for a range of applications including:

- Ingredient processing

- Waste water handling (packing)

- Bulk transfer

- Beverage pumping

- Batching

- Filter press feed

- Food packaging

- Clean-In-Place (CIP) applications

- Wine pump over

- Receiving and unloading

These pumps are designed to maintain product purity, prevent contamination, and mitigate the risk of costly recalls. By choosing ARO’s food grade diaphragm pumps, you can ensure that all processes in your facility meet the necessary hygiene standards, which are vital for public health and the production of high-quality food and beverage products.

Typical Features of Food Grade Diaphragm Pumps

Food grade diaphragm pumps available on the market are designed to meet stringent industry standards, including FDA and CE 1935/2004 compliance. These pumps are engineered for high efficiency, often providing superior flow rates compared to other pump types, making them well-suited for demanding applications in the food and beverage industry.

Key features include:

- Stainless Steel Construction: Often made from stainless steel, these pumps provide durability and meet the highest hygienic standards, making them ideal for food and beverage applications.

- Solids and Particulate Handling: Food grade diaphragm pumps can handle shear-sensitive solids and particulates without degradation or damage, ensuring smooth and reliable operation in demanding environments.

- Gentle Product Handling: These pumps handle products gently and smoothly, avoiding any damage or degradation to the product, a task that centrifugal pumps often struggle to achieve.

- Dry Running Capability: The ability to run dry without causing damage to the pump, adding to the reliability and longevity of the equipment.

- Preservation of Product Quality: By avoiding fluid frothing or separation, these pumps help maintain product quality, making them ideal for applications in the food, beverage, and cosmetic industries.

Why To Choose ARO Air Operated Diaphragm Pumps For Food & Beverage Applications?

ARO provides a broad selection of FDA-compliant AODD pumps, drum pumps, and food process pumps. These pumps are capable of handling high volumes of food-grade liquids with varying viscosities, such as: