Advantages of Air Operated Double Diaphragm Pumps

Universal Fluid Compatibility

AODD pumps excel due to their positive displacement mechanism. This design utilizes an elastomeric diaphragm that expands and contracts within a sealed chamber. This enables AODDs to handle a broad spectrum of fluids, from low-viscosity liquids like water to highly viscous slurries and even corrosive materials. This versatility makes them a valuable asset in diverse industrial applications.

Simplified Maintenance Regimen

AODD pumps boast a remarkably simple design with minimal moving parts. This translates to a streamlined maintenance regimen. The reduced number of components minimizes downtime associated with repairs and replacements, ultimately leading to lower maintenance costs.

Favorable Life-Cycle Cost

The economic benefits of AODD pumps extend beyond the initial investment. Their lower upfront costs, coupled with simplified maintenance requirements, contribute to significant life-cycle cost savings. Additionally, the robust design and inherent efficiency of the positive displacement principle lead to long-term cost advantages.

Self-Priming Capability

AODD pumps possess a distinct advantage: self-priming. This implies they can initiate pumping even with fluctuating fluid levels or entrained air within the line. This eliminates the need for constant manual priming, significantly simplifying operation and reducing reliance on external equipment.

Intrinsically Safe Design for Hazardous Environments

Safety is a paramount concern in many industrial settings. AODD pumps utilize compressed air as the power source, eliminating the need for an electric motor. This inherently safe design eliminates the risk of electrical sparks, making them ideal for flammable or explosive environments. This characteristic ensures compliance with stringent health and safety regulations in such environments.

Shear-Sensitive Material Compatibility

The unique diaphragm design of AODD pumps creates a pulsating flow pattern. This inherent characteristic minimizes the shearing forces experienced by the fluid being transferred. Compared to pumps with rotors or impellers, this gentle pumping action makes AODDs well-suited for delicate or shear-sensitive materials that could be susceptible to damage by more aggressive pumping mechanisms.

Dry-Run Capability

Unlike many other pump types, AODD pumps can operate briefly without liquid (dry run) without incurring damage to internal components. This characteristic allows for temporary flow interruptions during operation without requiring maintenance interventions. This can be crucial for processes where short periods without fluid flow are unavoidable.

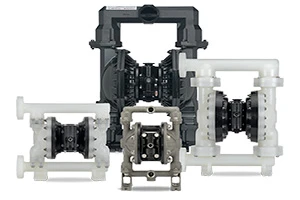

ARO Double Diaphragm Pumps

ARO is a widely recognized manufacturer of AODD pumps. Most ARO diaphragm pumps are ATEX certified (CE Ex11 2GD X). ARO double diaphragm pumps are known for their minimal and robust designs that target efficiency, accuracy, and ease of maintenance. ARO's EXP Series is a popular choice, offering high flow rates, a wide range of material and porting configurations, and automation capabilities through integration with the ARO Controller.

Conclusion

AODD or air operated double diaphragm pumps stand tall as a critical solution in the processes that employ administration of fluids in an accurate manner. Their production guarantees their ability to handle abrasive, corrosive and hazardous materials without sustaining much damage.

As we move forward in time, AODD pumps and the technology related to them is likely to evolve and advance. The future of industrial pumping does seem bright with the evolution of AODD technology.