Selecting the Right Piston Pump for Adhesive Applications

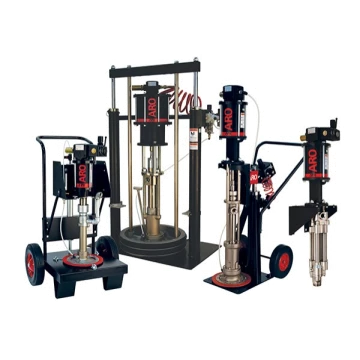

Due to the higher viscosities of adhesives and sealants, piston pumps usually offer the best performance. Based on material viscosity, two types of piston pumps are generally used:

- Chop-check pumps are self-priming and can move very thick fluid material. They are used in very high viscosity adhesive applications — up to and over one-million Centipoise (cPs).

- Two-ball pumps create a vacuum to pull fluid into the pump. They are used for adhesives of lower relative viscosity, or where the material must be moved more gently due to suspended beads or catalyzing agents.

By their physical nature, chop-check piston pumps generate a lower flow rate compared to 2-ball pumps. However, both types can be configured to operate within the same pressure range. As viscosity increases, a follower plate is often needed to help move the material from the container into the pump.

Many manufacturers use specialty adhesives formulated specifically for their applications. When integrating piston pumps and in-line components, ARO distributors and OEM system builders pay very close attention to the special challenges and requirements presented by the specific adhesive or sealant used for your application.

Dispensing Solutions for High Strength Industrial Adhesives

New types of adhesives for industrial applications are replacing spot welding, rivets, and other fasteners. These custom formulated adhesives often provide labor and materials cost savings, reduced weight, and higher bond strength.

Used for both automotive and general manufacturing purposes, these new adhesives are applied using a wide variety of delivery systems. Fully robotic dispenser systems rapidly apply a precise, consistently measured bead of adhesive to pieces such as an unprimed body panel or windshield. Gun-based applicator systems are used by plant workers to manually apply adhesives to panels and parts during production line assembly.

To achieve a more consistent flow and bead of material during application, fluid regulators can be added downstream of the pump. This controls fluid pressure beyond the regulator, cutting fluid pressure to the desired level to ensure smooth delivery.